Fly Baby Construction

Updated November 10, 2016

Flybaby construction started in early July, 2010. I’d been thinking about building a FlyBaby for years and finally decided I could put it off no longer. I secretly hoped to complete it in time for the 50 anniversary in 2012, but that deadline came and went years ago.

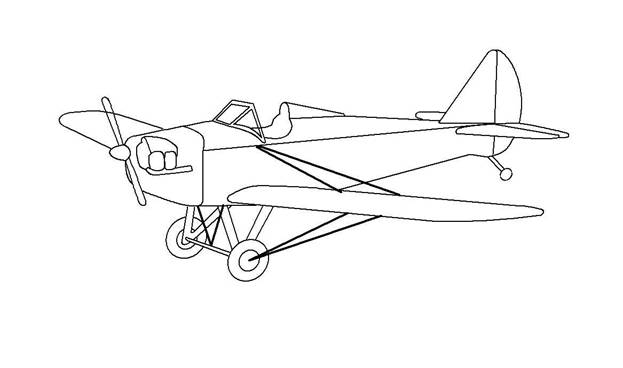

I choose a FlyBaby for a few reasons. I really like the way the plane looks. Open cockpit…nice lines, not too boxy, but not too complicated either. It’s made of wood, and I thought my model airplane building skills would be transferrable. (I was wrong. Turns out Spruce and Douglas Fir are a lot harder to glue than balsa wood.) I live in Bellevue, WA, just outside Seattle. Pete Bowers, the designer of the FlyBaby lived in Seattle, so there’s a bit of a bond.

A good friend, Michele Boland, first turned me on to the Flybaby many years ago. Ron Wanttaja’s web also provided inspiration. (http://www.bowersflybaby.com/) And, my very supportive wife, Lisa, surprised me with a set of plans for my Birthday a few years ago.

Spruce wood is really expensive, so I’ve opted to use at least some Douglas Fir. Vertical grain Douglas Fir is available at most decent lumber yards in my area, but Comptons in Seattle has the best selection. I did find a few VG Spruce boards at one place, but nothing you’d use for spars. I will likely purchase my spars from Wicks or Aircraft spruce when it comes time to make the wings. I hand selected all boards but still had to reject portions of the wood that were not quite aircraft quality.

To start, I had no wood working tools except a scroll saw, bench sander, and a few hand tools. I quickly purchased a table saw, miter saw, and planer, followed by a band saw and drill press. And finally a metal cutting bandsaw, and various hand drills. The tools take up a lot of space, but I’ve made good use of all of them. I don’t regret purchasing any of them.

A note on gluing wood… Gluing is trickier than I expected. The balsa I use for model airplanes is absorbent, and sucks in the glue to create a strong bond. Doug Fir is much less forgiving. I’m using T-88 Epoxy from Systems 3. It’s easy to mix, but despite claims, its gap filing properties are limited. It slowly runs out of any gap unless you can somehow hold it in place. Clamping is essential for strong joints. I did a lot of experimenting, and discovered that the worst way to glue to sticks together was to press them together by hand then leave them to dry. It seems they separate just enough that you’ll get voids. You can easily break the sticks apart with your bare hands. The instructions with the Epoxy state that over clamping can also result in a weak joint, but you most definitely want some clamping pressure.

|

|

|

|

|

Wings – Coming Soon! (OK…maybe in a couple years) |

|

|

|